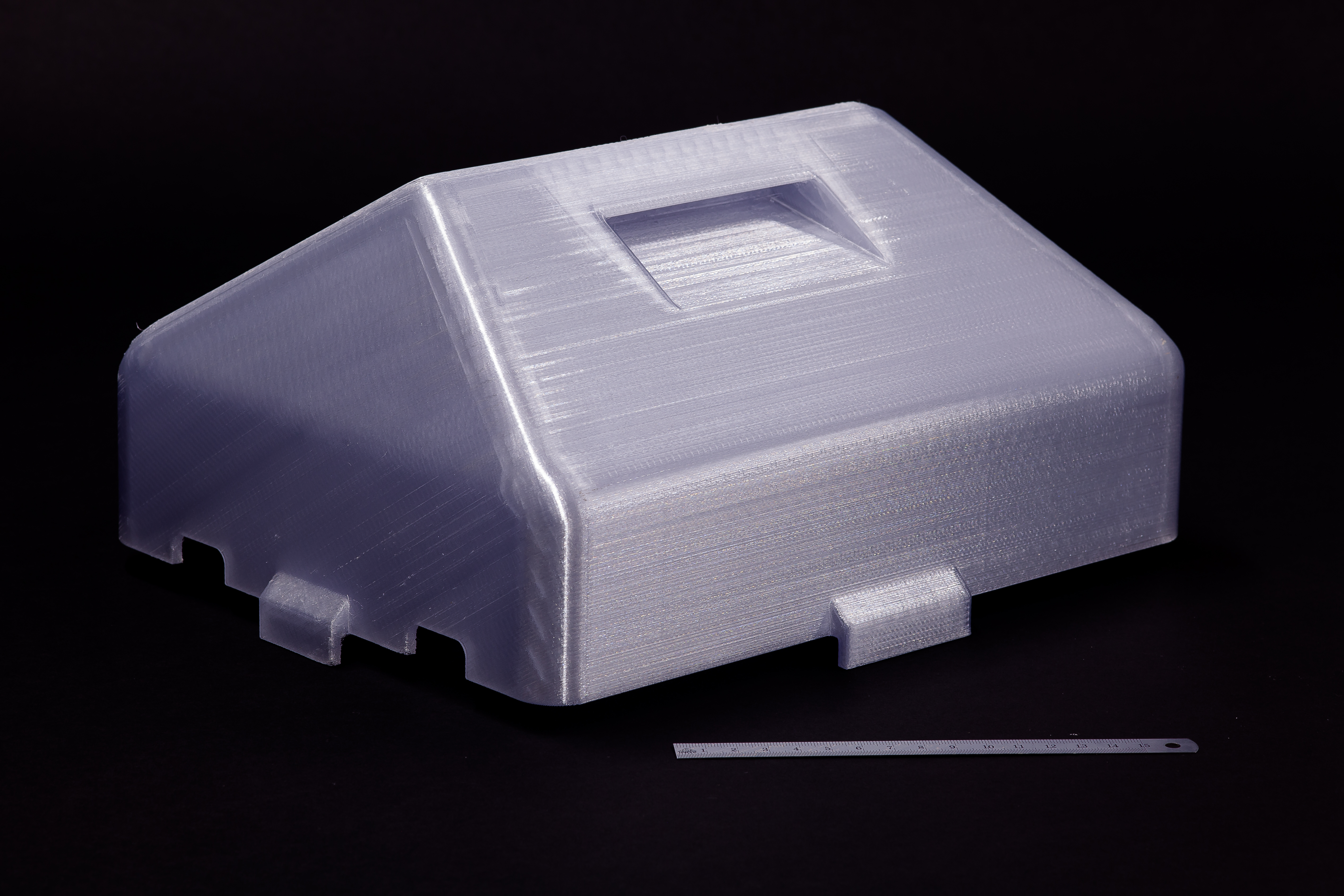

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a AM technology widely known for its speed, accuracy, and competitive cost. FDM parts are very rigid, especially compared to selective laser sintering (SLS), which makes them a great fit for projects with a rigidity requirement.

FDM is an additive manufacturing process where a machine precisely extrudes melted plastic filament to create a part.

Producing parts in FDM is broken up into 3 steps: pre-processing, production, and post-processing.

Pre-Processing: Printer software slices 3D CAD file into layers. For each slice, the software converts the data into machine code (also known as G-Code) that determines tool paths for the machine to follow.

Production: An extruder head melts and extrudes liquefied plastic filament along the tool path layer by layer until the part is completed bottom-up.

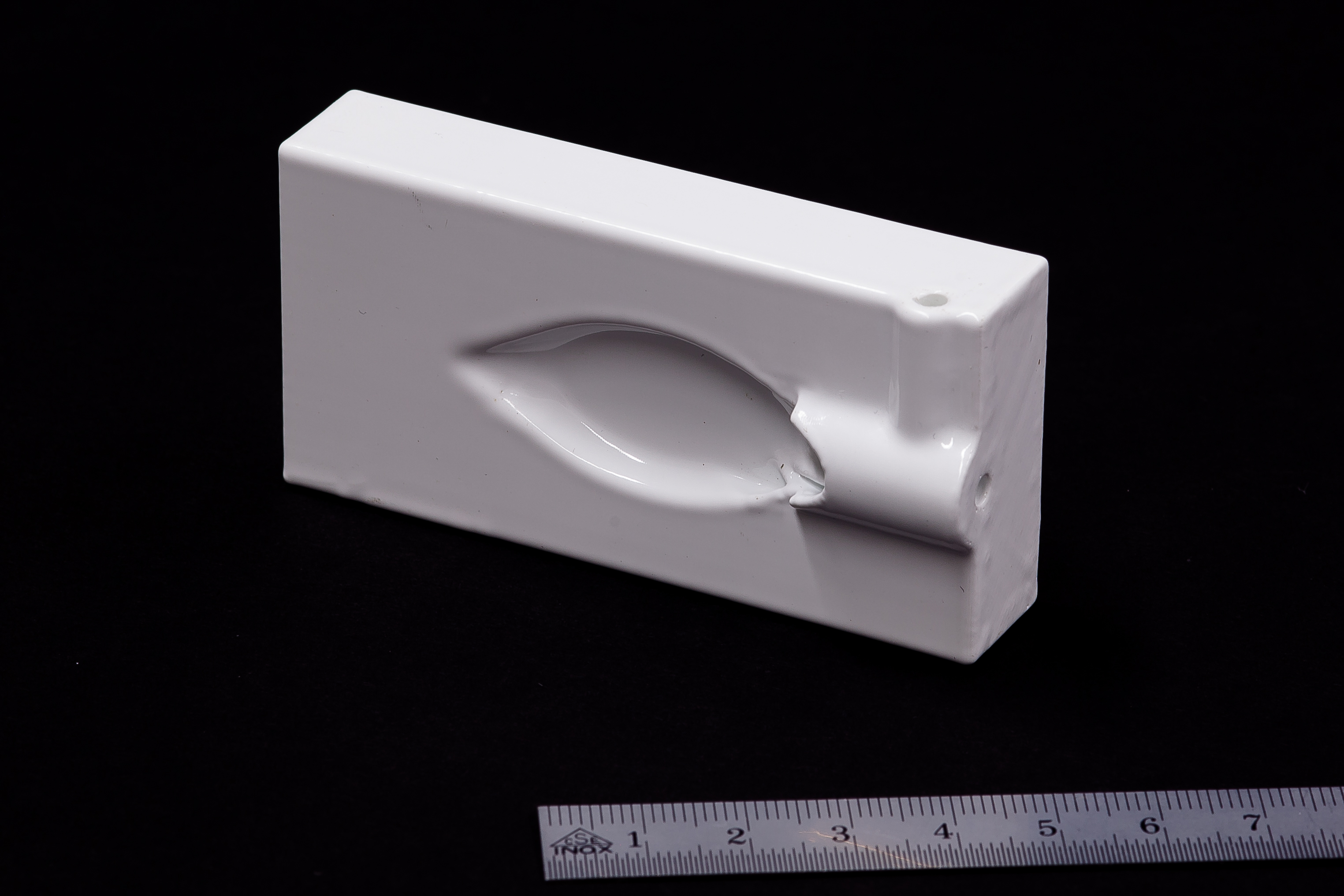

Post-Processing: The support material is removed by either dissolving it in water or breaking it off. More custom finishes such as surface smoothing, tapping, inserts, etc. are then applied.

Advantages / Disadvantages FDM

FDM is a cost-effective and very quick additive manufacturing process, especially for rapid prototyping or low-volume production. Fused deposition modeling works with standard materials. Therefore, parts have good mechanical properties and are durable over time. Parts can be post-processed as any plastic part produced with conventional manufacturing.

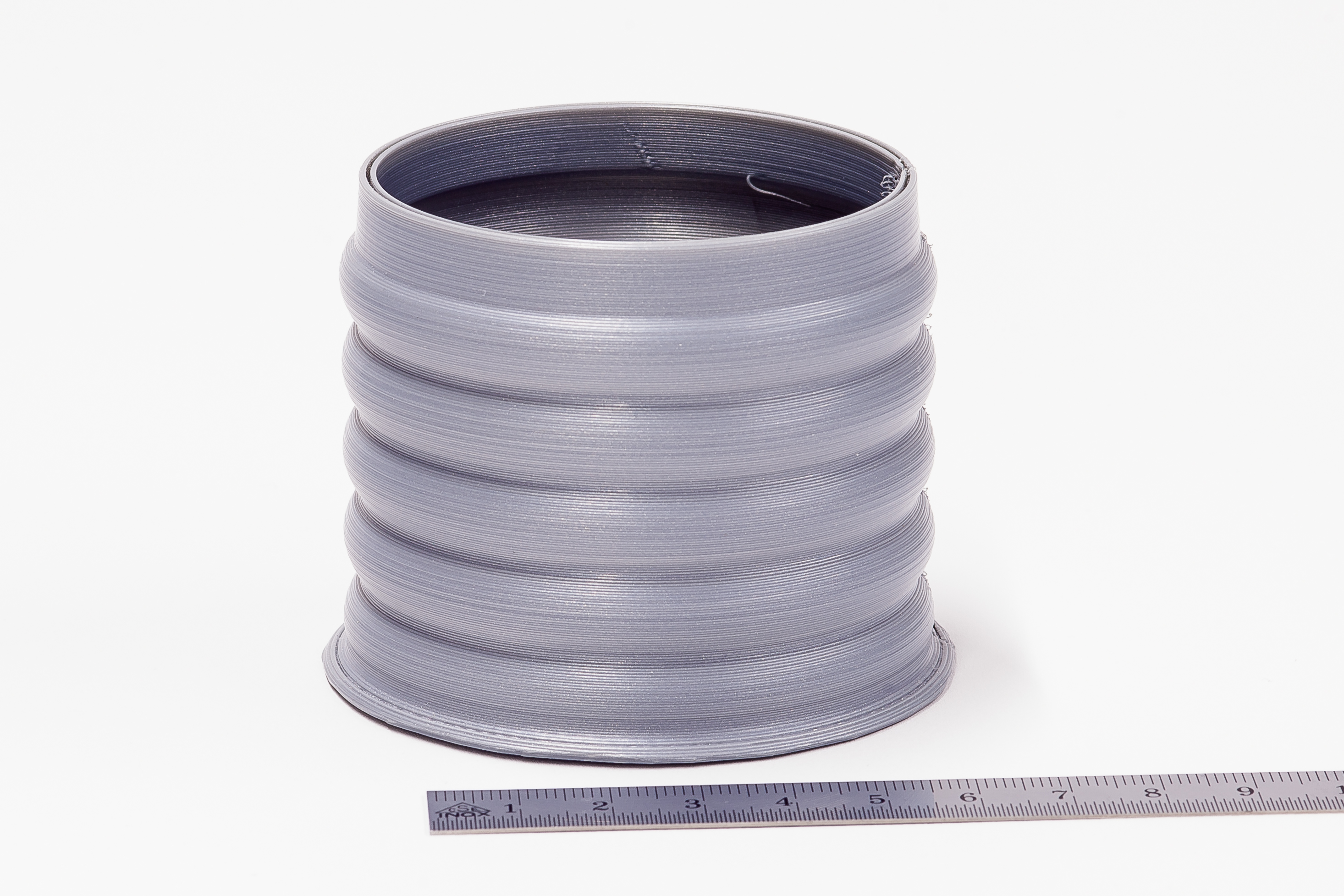

A disadvantage is however that the deposition of extruded material layer-by-layer, this will make the parts have an anisotropy in the z-direction (vertical direction) and the surface has a step-structure (surface smoothing is possible) and fine details cannot be realized.

Ideal applications for FDM

- Low-volume production of complex end-use parts

- Prototypes for form, fit and functional testing

- Prototypes directly constructed in production materials

Which material is available

ASA black provides UV stability and superior aesthetics in consistently high-quality parts. The material’s UV resistance makes it well-suited for end-use parts for outdoor commercial and infrastructure use. Soluble support material enables hands-free removal.

More materials are available in cooperation with external manufacturers.